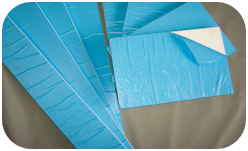

Custom Lamination

NOFP offers a variety of lamination techniques designed to meet our customer’s specifications. Our applications include an impressive selection of substrates, including expanded polystyrene, polypropylene, polyethylene, film, foil, bubble, paper, corrugated sheets, VCI corrosion inhibitor and fiberglass. We feature Roll-to-Roll applications such as film / foam, Roll-to-Sheet applications such as foam / foil, and Sheet-to-Sheet applications such as corrugated / foam.

Glue Lamination

- Widths up to 76″

- Diameters up to 6′

- Pressure Sensitive Adhesive

- Tri-Lam (three substrates)

- Roll-to-Roll lamination

- Roll-to-Sheet lamination

- Sheet-to-Sheet lamination

- Film-to-Sheet lamination

Glue Roll Coater Lamination

- Sheets up to 48″ wide / 30′ & longer

- Thickness up to 4″

- Pressure Sensitive Adhesive / Water based / Custom

- Film-to-Sheet lamination

Heat Roller Lamination

- Widths up to 73″

- Diameters up to 4′

- No adhesive

- Tri-Lam (three substrates)

- Roll-to-Roll lamination

Flame Lamination

- Widths up to 76″

- No adhesive, high speed

- Used for difficult to laminate substrates

- Roll-to-Roll lamination

- Tri-Lam (three substrates)